A problem solver

Dolphin Drilling AS uses Axess TRIM concept that involves setting up a good set of plans for the implementation of DROPS inspections, RBI (Risk Based Inspections), expert controls, drilling control and closure of findings. The companies are working together to find the best solutions to ensure maximum uptime and no injuries.

For us to make the right decisions, we depend on a sound basis. We experience Axess as thorough and effective. Continuity is also important for us. Axess is a young company with many young people, but our experience is that they have solid professional expertise. The Axess people on our rigs have extensive experience and know us and the rigs very well. It is important that the same people are on the same jobs over time, says Johnsen, who points out that this can be a challenge for a company that is growing quickly, as experienced employees often end up behind a desk in administrative roles.

Closure of findings

Axess is committed to being accessible and flexible. Flexible in terms of adapting the solutions to the various needs of a given time, and available in terms of being there when the customers’ needs is actually there.

We are very satisfied with the follow-up we get from Axess. The feedbacks from the rigs are good. The combination of being there on short notice, providing expertise, equipment and technology with high standard, makes us very satisfied with the job done, says Johnsen who has over 30 years’ experience in the maritime industry.

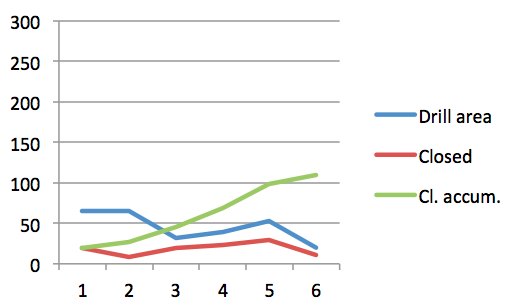

Axess takes responsibility for the entire process. They’ll not only find errors and potential hazards and pass the ball back. They also close findings. A summary of the findings on DROPS inspections at three Norwegian Dolphin Drilling rigs over the last three years, show that the systematic work gives results. Only on Bideford the number of findings has gone steadily down from 65 in July 2009 to 4 open findings after inspection in January 2013. The tendency is the same on the other rigs.

Statistics show that we limit risk and increase the uptime of equipment through continuous improvement. When we take responsibility for the entire improvement process from planning, inspections and reporting for improvement, documentation and maintenance program, we become a full partner in our projects. This gives our clients the continuity, safety, quality and not least lower cost, as we cut the number of mobilisations offshore, says Department Manager Knut Stefanussen in Axess.

Bideford Dolphin

Number of findings per inspection and the number of closed discovery.