USING A RISK-BASED APPROACH TO ENSURE ASSET INTEGRITY

Asset Integrity Management

Asset Integrity Management (AIM) is important to achieving safe and reliable operations, as well as avoiding unplanned downtime and incidents.

With over two decades in the oil and gas industry, Axess Group has extensive experience in AIM for offshore assets, to ensure their integrity throughout their lifecycle. To date, we have performed annual inspections on more than 150 different offshore units worldwide and provided integrity management services to more than 300 different installations.

Why Axess?

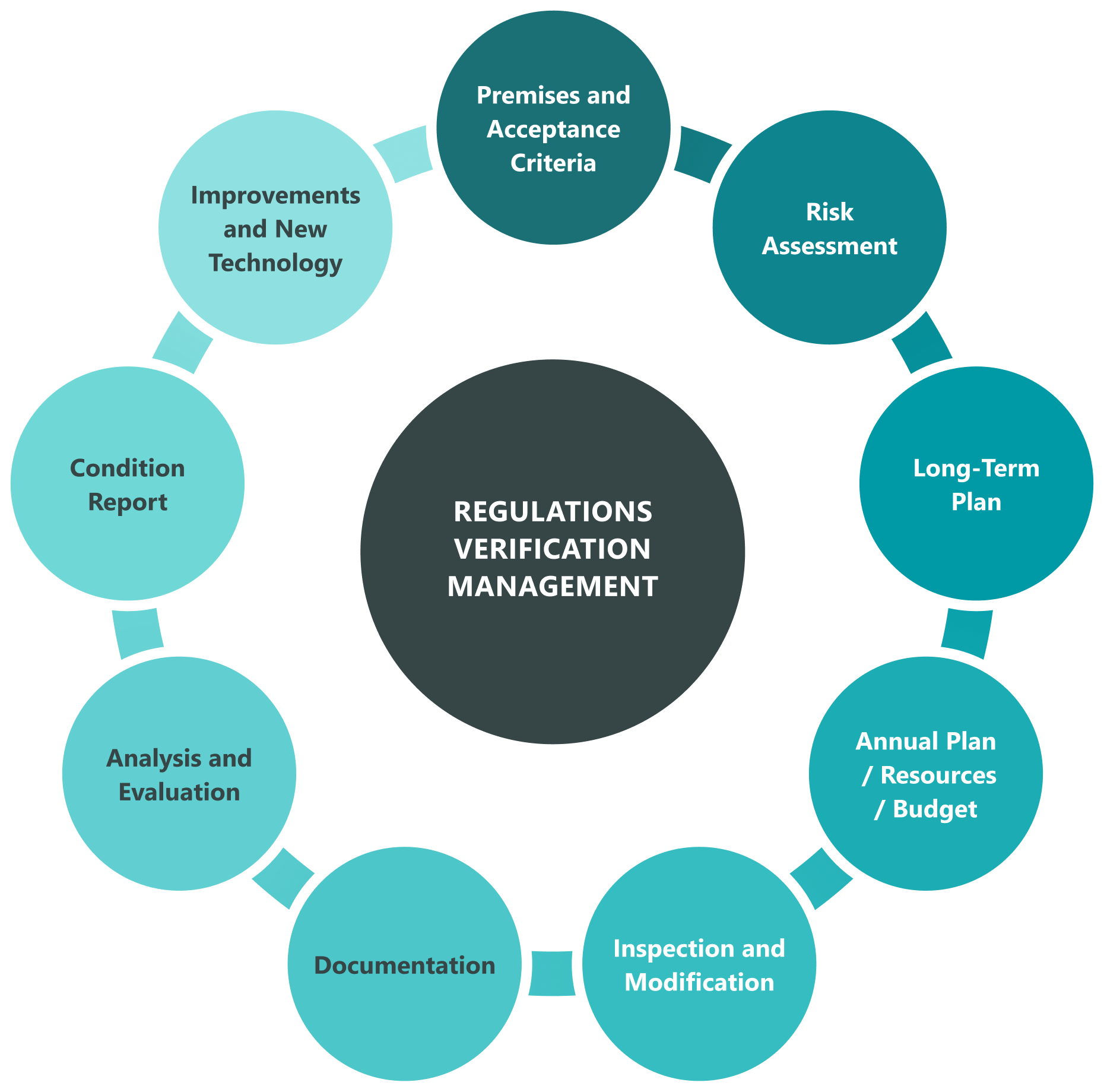

Axess Group can support you in the development of an effective AIM system that covers various asset components, including static pressurised equipment, dynamic pressurised equipment, hull and structures, as well as subsea equipment. Our AIM framework integrates performance analysis and integrity evaluation with meticulous documentation and direct communication to develop an overarching work process applicable to various assets.