Mitigating the risks of dropped objects

Operators have identified that the underlying cause of dropped objects is lack of procedure: insufficient hazard identification and risk control prior to conducting lifting operations, as well as non-compliance with the job-specific lifting operations manuals and procedures. The absence of preventive maintenance consequently results in failure of equipment due to inadequate understanding of corrosion risks, lifting equipment design limitations and poor inspection regimes.

Adequate procedures and training

All personnel working in DROPS exposed areas on the vessel — rig managers, technical superintendents, stability section leaders, safety officers and other relevant personnel—should have a basic introduction and training to the best practices for prevention of dropped objects. The company dropped object procedures must be pursued and distributed by both the company HSE and senior management; these documents must be active and dynamic over time. A top down approach to dropped object prevention ensures the company is thinking about the issues in all aspects of their work and at all levels within the organisation.

Execution of drops inspections

Along with absolute ownership to the challenges with DROPS from management and crew, implementing a DROPS inspection system by a competent engineering inspection provider has proven to be a crucial preventive measure for mitigating risks associated with dropped objects. Frequent inspection regimes contribute to DROPS awareness and increased knowledge to prevent falling object incidents.

Secondary retention

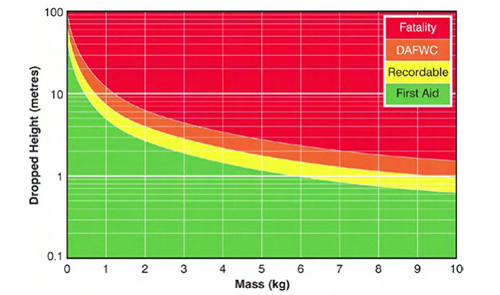

Correct materials for secondary retention—safety-wiring, lock nuts, carabiners, cotter pins, safety netting etc.— must be installed on equipment in locations with present a high risk in the event of failure. The DROPS Calculator should be used when determining required securing among other factors, such as items location, materials etc. (see figure 1).. It is important that spare securing items are available for crew. The cost for storing a few secondary retention materials onboard is very low but the HSE advantage is very high.

Closing of findings

It is critical to implement the corrective action based on the inspection’s findings to promptly eliminate the chances of a workplace incident. Don’t let the findings stand untouched until the next annual inspection.

Conclusion

As maximum uptime and production is the main goal of stakeholders, avoiding accidents should always be top priority. That said, employing an independent inspection body that can help implement an efficient dropped object prevention plan and long-term inspection routine, is essential to maintain utmost safety without causing operational disruption whilst protecting your reputation.

Axess Group’s DROPS management system and inspection program is a systematic approach to reduce the risk of dropped objects while ensuring compliance and HSE. We have carried out dropped object inspections on drilling platforms, FPSOs, MODUs, fixed platforms, FLNGs and onshore plants to the oil and gas sectors around the world. Axess Group is a certified member of Dropped Objects Prevention Scheme Global Resource Centre (DROPS Online).

Contact our DROPS Engineering department for future collaborations at [email protected].

Cover photo: “Ocean Star Drilling Rig” by Ed Schipul is licensed under CC BY-SA 2.0