Structural Integrity Management Inspection History as a Tool

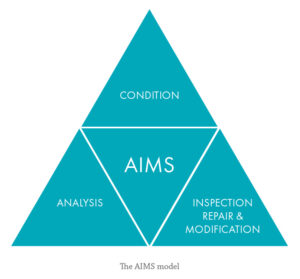

Many rigs are operating far beyond the initial design fatigue life. But with old age comes long experience. Axess assess the extensive inspection and crack history with a reliability-based integrity program called AIMS (Assessment Integrity Management Structure) to make clients able to extend service intervals for aging units from 2.5 to 5 years. Axess challenge the conservative assumptions from the structural analyses made. The actual fatigue life of a structural member depends very much on the small details.

Axess Structural Integrity Management (SIM) department has trained structural engineers with knowledge and emphasis on the effect fabrication quality, detailed design and small modifications have on actual fatigue life. On some rigs Axess also performs strain gauge measurements at special areas for years to be able to adjust structural analysis models and help achieve longer and more realistic fatigue life values.

SIM also has a highly experienced Marine Structural Analysis team which can do new global and local analyses on both the maximum loads from extreme weather on the hull and the fatigue of repeated loads from operating in harsh conditions year after year. More importantly our team assess the extensive set of analyses performed by others, helps the client verify them and make decisions as a result of them.

Renewal Survey

Axess uses the AIMS follow up regime extended with a level of detail more extensive than the standard DNV IIP. It has detailed in-service fatigue analyses, RBI analyses, including inspection history and is further extended with As-is description and improved follow up regime for inspection repair, modifications and weld improvement. AIMS has a probabilistic approach that assesses the findings compared to what theory predicts. Axess uses the inspection results to modify the in-service inspection program.

When planning a renewal survey, the structural integrity engineer goes through the findings since last RS, defines or calculates accept criteria from the structural analyses and regulations and decides which findings need repair or modifications and what measures to take.

The yard stay is also the time to do bigger structural modifications to increase payload or stability. Some clients use Axess as a structural integrity partner to help control these projects. Axess assess which structural analyses the client’s sub supplier must provide and help verify the results. Reading through the reports is not sufficient quality assurance when it comes to structural analysis but one needs to go through the models run.

Verifying the results from the client’s perspective is important to control what actually needs to be done. At a yard stay the suggested modifications are many but taking the correct actions is key. Doing many modifications does not help if the important one is missed. Axess helps the client maintaining the level of safety while also controlling the modification scope.