Integrating AI engine into 3DView application

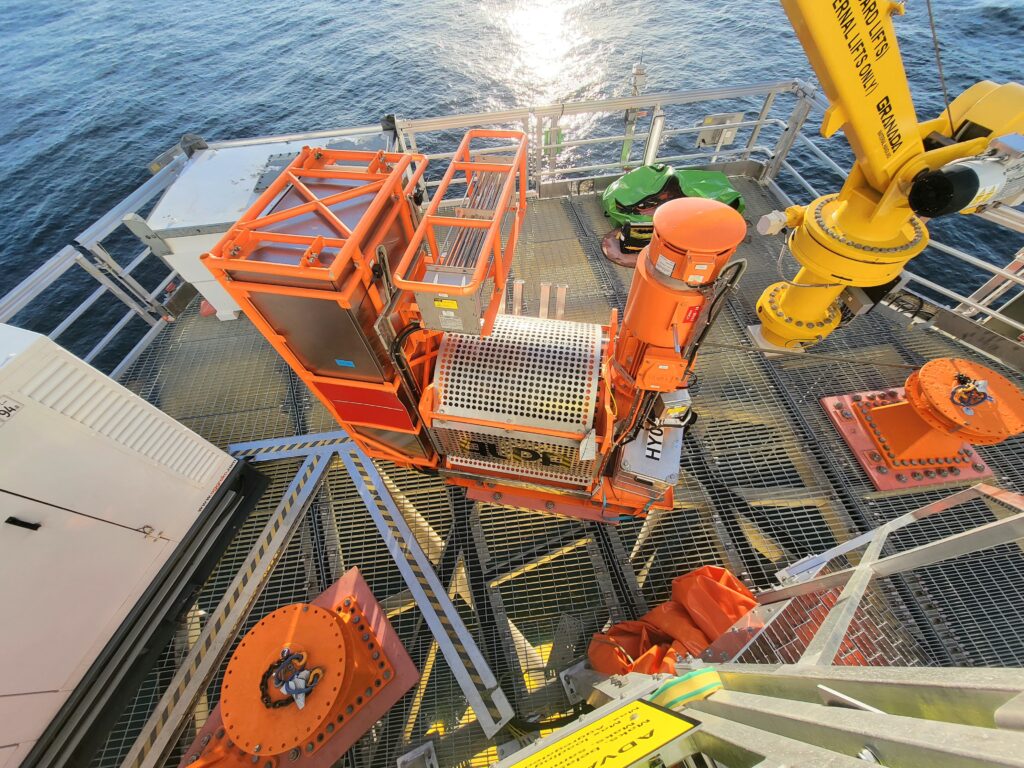

MOLDE, Norway, January 10, 2024 – Axess Digital has enhanced the 3DView application launched in 2023, by integrating an Artificial Intelligence (AI) engine. As part of the suite of applications within the inspection software, Bridge, the purpose of 3DView is to enable seamless collaboration and sharing of 3D models, eliminating the need for specialised hardware or software.

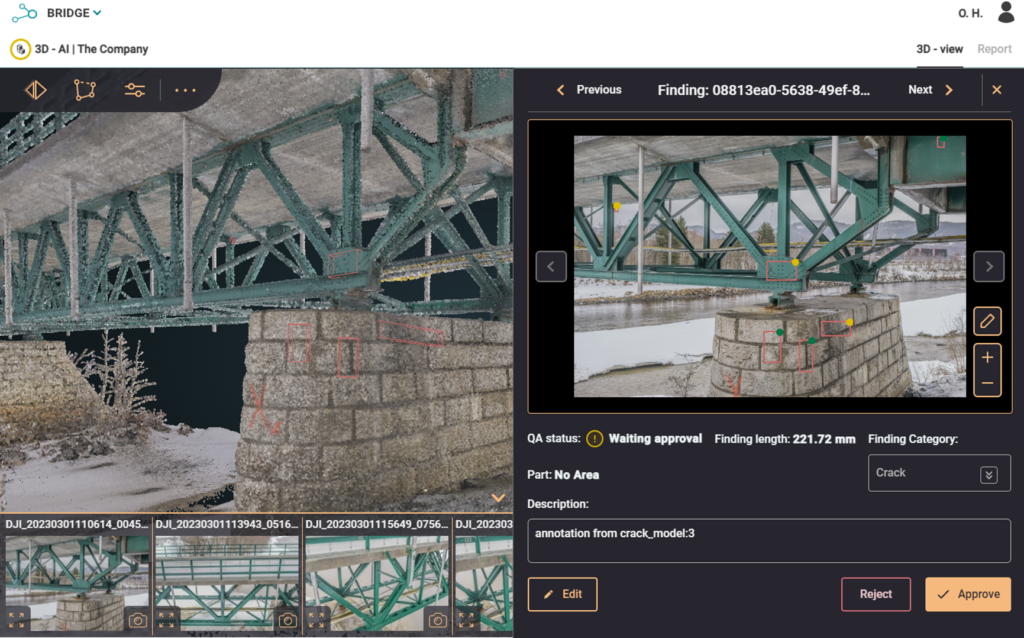

The AI engine was developed to enhance efficiency by streamlining the inspection process. Upon uploading data to the application, the AI identifies defects before users verify the accuracy. This is an ongoing process, where any corrections made by users will be utilised as training data for developing new AI models.

Additional enhancements include the capability to view images in a carousel and the option to filter images with annotations from users or AI. It is also possible to divide the 3D models into zones for more precise reporting and to assist in monitoring inspection progress. The solution also pinpoints the locations of defects in the images on the corresponding 3D model, enabling the identification of unique defects and the calculation of lengths and areas. This approach facilitates the efficient evaluation of defects suggested by the AI, and enables users to conduct manual inspections on specific parts of the 3D model.

All processes and data are run and stored in Microsoft Azure, offering the best security and reliability within the industry. In addition, Axess Digital will soon obtain ISO 27001 certification. Conformance to the globally recognised standard for information security management systems, underscores its dedication to IT security, cybersecurity and privacy protection.

“To date, we have utilised this application to inspect bridges and tanks for cracks. Our commitment is to continuously enhance productivity and efficiency for clients by consistently improving the capabilities of our AI models. This involves detecting more defects with greater accuracy, while ensuring the security of all information,” Ole-Erich Haas, Head of Product Development at Axess Digital said.