Rig preparation for Saudi Aramco in the Middle East

Client: Global offshore drilling contractor

Industry: Drilling

Asset: Jackup rig

Location: ASRY, Bahrain

Year: 2023

Challenge

The client required one of its rigs to be prepared before handing it over to Saudi Aramco as part of a new contract.

Axess Middle East was contracted to ensure that the asset is in optimal working condition, meeting safety, regulatory and Saudi Aramco’s standards.

Solution

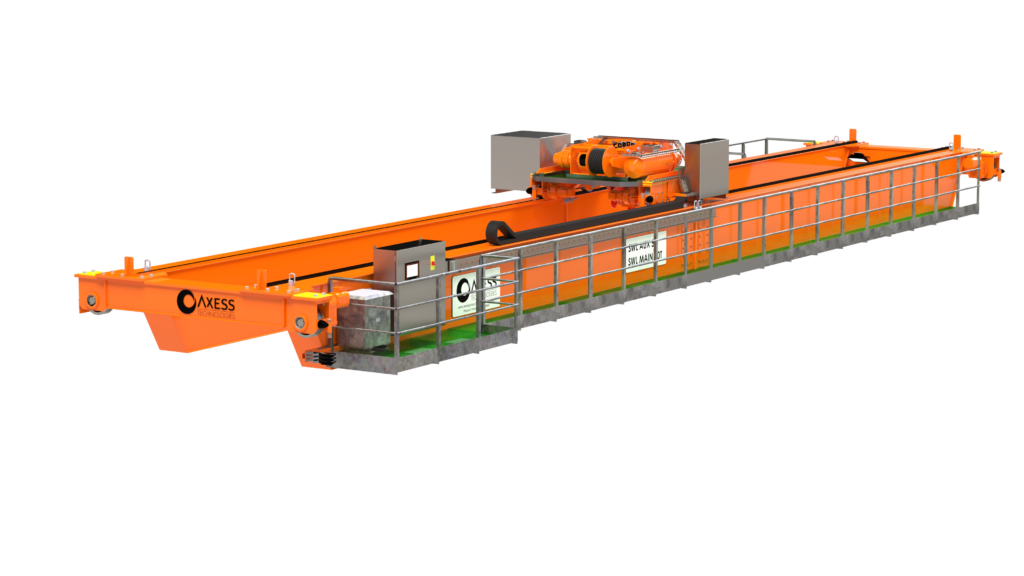

A comprehensive scope of work was carried out at the Arab Shipbuilding and Repair Yard (ASRY) in Bahrain, including complex rigging such as the installation of travelling block and top drive, commissioning of critical equipment like the crane engine, as well as essential mechanical and electrical works.

Given the demanding timeline and the need for a wide range of skills, personnel from our global offices in the region, namely, KSA, UAE, India and Singapore, were mobilised to work on this project.

Results

The team worked tirelessly to carry out the project smoothly within the tight window. Over 8,500 man-hours were dedicated to the project without any Lost Time Injuries (LTI).

“We are happy to have exceeded the client’s expectations in terms of mobilisation and execution speed. This project has demonstrated our shipyard capabilities. Our two-decade partnership has seen us support the client in various locations worldwide. With our strategic presence in the UAE and KSA, we look forward to continued collaboration,” Ravi Mishra, Regional Manager – Middle East at Axess Group said.