Optimising offshore installations inventory through data-driven solutions

The information covered a span of more than three years with a total of 345 assets worldwide, ranging from fixed installations, mobile offshore units and FPSO vessels.

One of the key analyses derived from the study was how the vast amount of inspection data could be an effective tool in optimising any offshore installations’ inventory. Read on to discover insights that will help you reap operational benefits from our historical inspection data.

Predictive analysis between similar rigs

Our data show that similar installations have huge differences in the amount of lifting equipment inventory, nevertheless, the in-depth analysis presented by affinity rigs could provide key knowledge that can predict future failure patterns. By utilising historical data associated with inspection, repair and maintenance records of similar rigs, we can strategically advise what type of equipment would yield the best result, how much quantity is needed, how often the equipment needs replacement, or which types of gear have the least number of faults.

Our improvement reports, systematically categorised into organisation, technical and design, allow us to deliver higher precision analysis for future maintenance requirements of similar rigs.

Achieve maximum productivity

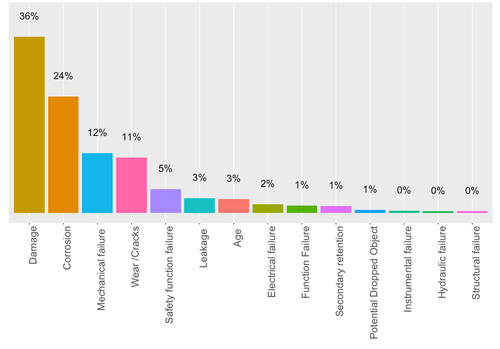

Majority of the technical incidents we have gathered associated with lifting equipment are mechanical damage (38%) and corrosion (24%). Lifting equipment failure often results in costly down-time, and may cause disastrous impact in the rig’s operation on extreme cases.

By analyzing the similarities between incident reports in our database, we can optimise the time allotted for inspection and maintenance, allowing rig-owners to focus on the most important part of their operations. The information and evaluations provided in our report allow us to advise the most suitable equipment inventory that can yield maximum productivity on any offshore installation type.

Identify cost-saving opportunities

In the upstream industry, it is very common for asset owners to hold too many items on their offshore assets, nevertheless, our data-driven solutions can optimise the costs associated with the purchase and subsequent maintenance of these equipment. E.g., assets with too much lifting equipment has a negative effect on the company’s annual inspection budget due to the excessive associated costs in maintaining, certifying and registering of potentially redundant equipment. Having an optimised procurement plan based on the information provided by Axess’ data mining, we can optimise our clients’ inventory, prevent expensive down-time and long lead times, allowing them to save time and costs in the long run.

Establish inventory for newbuilds

Optimised equipment inventory plays a key role in ensuring the reliability and safety of newbuild offshore installations. Through our vast maintenance history on newbuilds, we have a competitive advantage in analyzing which maintenance activities are really needed, identify potential cause of failure and implement the lessons learned from the past. As a result of our experience and data capture, Axess are able to assist in creating the necessary maintenance schedules for various lifting equipment and machinery onboard such vessels, allowing a simplified and streamlined approach to tackling maintenance and inspection needs.

In a nutshell

Overall, we strongly believe that the use of inspection data in optimising lifting equipment inventory can significantly reduce costs and time related to purchase, inspection and maintenance. Our goal is to focus inspection and maintenance where it is truly needed to facilitate efficient, cost-effective, sustainable and safe operations.

Disclaimer: The Lifting equipment inspection data is gathered from our database to give an informative presentation and should not be taken out of context. The use of the data must be approved by Axess Group. Contact us for more information.

*Equipᵀᴹ is a web-based system that our clients use to keep and demonstrate control of their offshore lifting equipment. Click here for more information about the software.